Oema honors the beauty of everyday life through objects made with intention and meaning. By creating long-lasting, grounding pieces that become part of personal rituals and memories, Oema seeks to foster a deeper connection with our homes and stories, and the simple acts that shape our lives.

FOUNDER

The word Oema is derived from the letters of the sentence "Mario oleiro" in Portuguese, which translates to "Mario the potter". Mario de Souza was Ana’s grandfather and a highly skilled potter.

Ana de Souza is a Brazilian designer and ceramicist behind each Oema piece. When founding Oema, she drew on her grandfather's and great-grandfather's pottery legacy to create contemporary and deeply personal work. She combines modern design sensibilities with a sentimental touch, creating both functional and meaningful pieces. The act of shaping ceramics became, for Ana, a way to honor memory, place, and time. This unique blend creates the essence of the treasures that carry the Oema name.

PROCESS

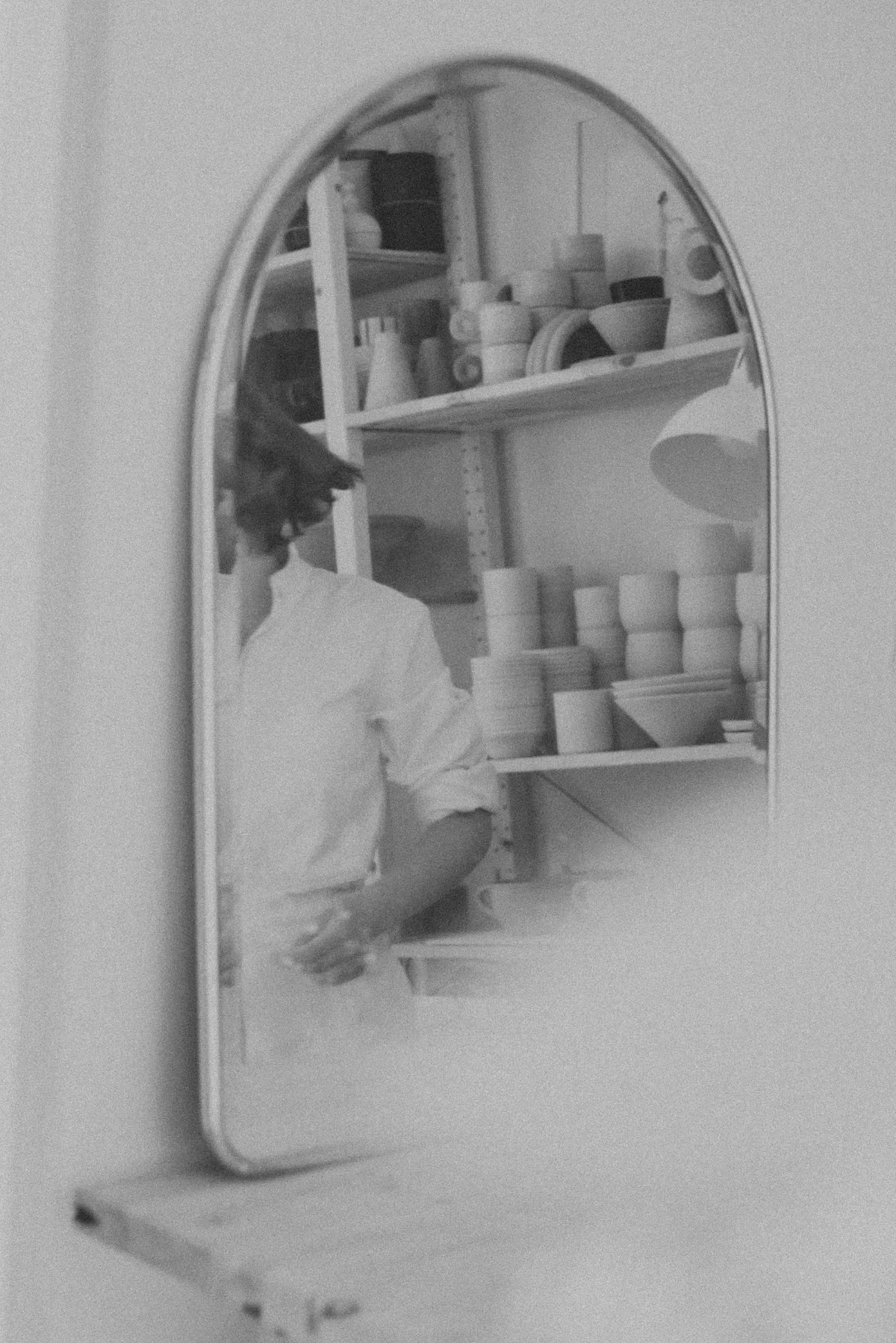

Crafting ceramics is a time-intensive process that requires patience and attention to detail. At Oema, Ana personally models, finishes, and glazes each piece of ceramic at her private studio in Barcelona.

Before the shaping process, the clay is prepared by being weighed and wedged until it becomes homogenous and air pockets are removed. Using a potter's wheel, water, and various tools, Ana handcrafts each piece of ceramic.

After a day of drying, the shaped piece is ready to be trimmed, and the base is finished and stamped. Depending on the design, additional touches are made while the piece is still slightly moist. Carvings may be added, and handles may be attached.

Once the piece has dried for a few days, it's ready for the first firing. The bisque firing process takes two days and reaches temperatures up to 950°C.

After the bisque firing, the pieces are glazed using various techniques that depend on the design. After one day of drying, the glazed pieces are ready for the high-temperature firing, which takes two days and reaches temperatures up to 1250°C. The result is a functional and food-safe piece of ceramic that is designed to last for many years to come.